Skip to main content

Skip to main content

| Home / Information / Bar Code Basics Primer |

| A Bar Code Primer, ©1997-2021 Worth Data | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

Contents | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| What's in a bar code? | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bar Code Structure | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

When a bar code scanner is passed over the bar code, the light source from the scanner is absorbed by the dark bars and not reflected, but it is reflected by the light spaces. A photocell detector in the scanner receives the reflected light and converts the light into an electrical signal. As the wand is passed over the bar code (in the above illustration), the scanner creates a low electrical signal for the spaces (reflected light) and a high electrical signal for the bars (nothing is reflected); the duration of the electrical signal determines wide vs. narrow elements. This signal can be "decoded" by the bar code reader's decoder into the characters that the bar code represents. The decoded data is then passed to the computer in a traditional data format. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Types of Bar Codes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

There are lots of different bar codes. Some bar codes are numeric only, (i.e. UPC, EAN, GS1 DataBar, ITF Interleaved 2 of 5). Some bar codes are fixed length, (i.e. UPC-A is 12 digits, UPC-E is 6 digits, EAN-13 is 13 digits, EAN-8 is 8 digits, and GS1 DataBar is 14 digits). Some bar codes can have numbers and alphabetic characters, (i.e. Code 93, Code 128, and Code 39). One bar code allows you to encode all 128 characters, (Code 128) while 2D bar codes allow you to encode a lot of data into a small space (PDF417, Data Matrix, QR, and MaxiCode). Many were invented some time ago

and have been superseded by newer bar codes.

Some industries standardized on older bar codes

before the better ones had been invented, thus

there is a continuing requirement for their use

in particular industries.

Many readers have to comply with their customer's or industry's bar coding specifications; no choice is possible, just compliance. Look at the following samples of printed bar codes:

The classic bar code type is Code 39, (also called Code 3 of 9) which has 9 bars and spaces; three are wide, and the other 6 are narrow. In Code 39, 3 of 9 total bars and spaces are wide; hence the name, Code 3 of 9. For example, look at the following character representations with Code 39: Notice there are two widths of bars and two widths of spaces. If you wished to print a bar code of ABCD, you would need to start and end it with a special Start/Stop code character - the * (asterisk) is used for Code 39. So to print a bar code of ABCD, it would need to be printed as *ABCD*. There should be at least 1/4" of white space to the left and right of the code; this helps the reader pick out where a bar code begins and ends.

Other bar code types are similarly constructed. UPC and EAN bar codes have four widths of bars and spaces; so does Code 128.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bar Code Selection Recommendations | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

The larger the width of the elements, the more space it takes to print the bar code; therefore, the lower the bar code density. The thinner the bar and spaces, the less space is required and the higher the bar code density. Look at the samples below of different densities:

Lower density bar codes are more reliably printed and more consistently read than higher density bar codes, because minor variations (due to printing or damage) are much more serious with high density bar codes - the percentage of distortion is larger. |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Bar Code Readers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

There are three basic types of bar code readers: fixed, portable

batch, and portable RF. Fixed readers remain attached to

their host computer and terminal and transmit one data item

at a time as the data is scanned. Portable batch readers

are battery operated and store data into memory for later

batch transfer to a host computer. Some advanced portable

readers can operate in non-portable mode too, often eliminating

the need for a separate fixed reader. Portable RF Readers

are battery operated and transmit data real-time, on-line.

More importantly, the real-time, two-way communication allows

the host to instruct the operator what to do next based on

what just happened. USB Keyboard Interface Bar Code ReadersThe standard interface available for bar code reading on a Personal Computer is a USB interface. PC’s with Windows® 10, 8, 7, Vista, or XP, Apple® computers running macOS & Mac OSX, as well as computers running Linux support USB HID keyboard attachment.

Worth Data offers USB interface - enumerating as a standard USB HID Keyboard - on all of our Laser Scanner models - LZ165-USB, LZ365-USB, and the 530-2D-USB 2D imaging scanner - as well as the SLV-USB slot badge scanners, and the RF Laser Scanners with a B700 USB Base Station. How Does It Work: Worth Data Keyboard Bar Code Scanners

Our TriCoder Portable readers also feature USB, supporting both HID Keyboard mode as well as lighting-fast full speed USB 1.1 uploading (40+ times faster than through the serial port) is supported for uploading of data files and even firmware updates. Personal

Computer Keyboard Wedge Readers

|

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Gun Style Bar Code Scanners | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Wand | CCD |

Laser | |

|---|---|---|---|

| Cost | Discontinued | Discontinued | $179 - $229 |

| Limited on Width of Bar Codes Readability | None | up to 3-4" for

medium density codes |

12" Typical |

| Multiple Tries/Second | No | Yes | Yes 48-100 Scans Per Second |

| Distance Reading | CONTACT - 0.2" | 0.5" - 4" | 0" - 18" (Bar Code Dependent) |

| Irregular Surface Reading Capability | No | Yes | Yes |

| Moving Parts | No | No | Yes |

| "Can't Miss Reading" | No | Yes | Yes |

Integrated Readers

Many older bar code readers had

separate decoders boxes that a bar code scanner plugged into. All of our bar code scanners have the decoders integrated

right into the scanner, usually the handle. An integrated

reader is usually less expensive and saves the space

of the separate decoder.

Laser scanners have a very precise beam of light

which can be reflected accurately several

inches to several feet to read bar codes. Almost all laser

scanners today have a moving beam which

sweeps back and forth, or a beam that automatically spreads across the bar code.

inches to several feet to read bar codes. Almost all laser

scanners today have a moving beam which

sweeps back and forth, or a beam that automatically spreads across the bar code.

Some very low cost laser scanners require the user to move the beam across the bar code much like a wand, there is even one scanner that uses a spring loaded button that the user pushes to make the scan beam move. The advantages of automatic electronic laser beam scanners are:

Laser scanners emit a laser light beam which sweeps back and forth or is projected across the bar code anywhere from 48 times per second to over 100 times per second. At this rate, unsuccessful reading attempts go unnoticed; you will only be aware of the one successful decode. Once a read has occurred, the laser turns off, requiring you to release and pull the trigger again to reactivate the laser scanner and scan another bar code.

The lower the density of the bar code, the further away the laser scanner can read a bar code. The higher the density of the bar code, the closer to the bar code the laser scanner must be.

Triggered Laser Scanners

Triggered Laser Scanners are virtually "can't miss". Just "point and shoot". Face the bar code so that the bars point up (the laser light will then form a red line across the bar code when the trigger is pulled). Aim the gun scanner at a bar code and pull the trigger; reading is instantaneous. You may have to move the scanner closer to the bar code to get a read, but that's it. Triggered laser scanners are the easiest bar code scanners to use. The standard laser scanners read up to 1-12" distance, depending on the brand of the laser scanner.

To the left is the Worth Data LZ365-USB Laser Scanner, which has a 3 year warranty. It reads a standard 100% medium density bar code from 13 inches away.

We have tested the Worth Data LZ165-USB & LZ365-USB by hard throwing (not just dropping) them to the floor. They survived every repeated throw. The moving scan element of the LZ365-USB and the LZ165-USB lasers have a lifetime warranty and both scanners use a scan engine which is rated to withstand 2000G's of force on impact.We developed this laser scanner after years of frustration with other laser manufacturers' poor product reliability. Therefore, when we decided to manufacture our own laser scanners we selected the best laser engine components for our laser scanners we could. Being the manufacturer of the entire assembly, we can now more closely control function and reliability.

Below is a chart showing the reading range of most of the scanners we sell - including some of our products with laser scanner built right into the units like our TriCoder's and our RF Terminals.

Supermarket Slot Scanners

These devices are continuously emitting multi-directional light beams to maximize the reading of a bar code regardless of the orientation of the bar code to the scanner. Unless the bar code is on the surface of the item pointing straight up, the bar code reader has a good chance of reading it. These devices are required to be integrated into the sales counter. They typically directly interface with a retail POS terminal.On Counter Scanners

These devices are the smaller cousins of the Supermarket Slot Scanner. They were developed for the convenience stores that wanted automation but didn't have the counter space required for a slot scanner installation. They also have a omni directional light source to free the user to present the bar code in any orientation. They sit on a counter, or they sit on a stand that sits on the counter. Items are passed a few inches in front of the scanner to get a successful read.Industrial Scanners

There are also a whole line of scanners made just for industrial applications including small under $1000 scanners that read a few inches distance and large $20,000 long range scanners that read twenty feet away. These are typically mounted adjacent to conveyor lines to read bar codes on passing items; the host computer then directs the items to the appropriate branching line. A classic example of such scanners use is airport baggage sorting; (those bar codes that are placed on your luggage are actually used in the large airports to get your luggage to the right place -except Denver). This type of equipment is almost always sold with turnkey hardware (including conveyors) and software by specialty integrators. Sources for industrial laser scanners are:

Lazerdata Corp. 407-843-8975

Microscan 206-226-5700Long Range Laser Guns

There are hand held triggered long range laser scanners that can read up to 33 ft. distance, (using retro-reflective low density bar codes) or 17 ft distance using paper low density bar codes. Long range laser scanners are naturally more expensive than the standard laser scanners. Typically they would be used in large warehouses were scanning boxes high up off the floor is impossible or unwieldy with standard laser scanner.

The Worth Data 530-2D-USB scanners feature a upgraded high speed scan engine that is designed to read both standard 1D bar codes like UPC, Code 39, and Code 128, plus they read 2D matrix bar codes like PDF-417, DataMatrix, QR Code, MaxiCode, Postnet, IMBC, and many others.

The Worth Data 530-2D-USB scanners feature a upgraded high speed scan engine that is designed to read both standard 1D bar codes like UPC, Code 39, and Code 128, plus they read 2D matrix bar codes like PDF-417, DataMatrix, QR Code, MaxiCode, Postnet, IMBC, and many others.

The 2D Scanners have a very precise camera and high speed CPU that processes the large amount of date required to decode a 2D bar code instantly.

Our 2D Scanners are also omni-directional, which means that they can read a bar code in any orientation. All the operator needs to do is line up the aiming spot inside the bar code and it will read.

The 530-2D-USB Scanner operates as a USB keyboard, outputting the data as keyboard entry. The 530-2D-USB is a powerful yet easy to use reader if you need to read 2D bar codes - it even reads postal codes including the IMBC Intelligent Mail bar codes from the USPS®.

We also offer the same powerful 2D Scan Engine integrated into our 5200 TriCoders, our 72000 RF Terminals, and the LT7802 Wi-Fi Terminals). We also offer a wireless handheld gun scanner with a 2D engine in our 520-RF 2D Cordless scanner.

![]() Wand Scanners are the oldest, and now outdated, type of hand held bar code scanners.

A wand was typically made from 1/2" stainless

steel tubing, or from plastic; optics

are in the front with a cord out the

back. The wand scanner must be moved

by the user's hand across and in contact

with the bar code. While the wand is

moving across the bar code, the reflected

light is converted to electrical signals

through a photocell in the wand.

Wand Scanners are the oldest, and now outdated, type of hand held bar code scanners.

A wand was typically made from 1/2" stainless

steel tubing, or from plastic; optics

are in the front with a cord out the

back. The wand scanner must be moved

by the user's hand across and in contact

with the bar code. While the wand is

moving across the bar code, the reflected

light is converted to electrical signals

through a photocell in the wand.

A

wand requires a little technique; it

is not a "can't miss" scanner.

Even without directions, most people

can master the use of a wand in 30-45

seconds; but some need directions and

training for a few minutes to learn the

proper wanding techniques.

Wands can read any length of bar code. Wands typically can read through laminates of thickness up to 1/10" inch. Many wands can read through CD cases and audiocassette cases. Wands have mostly been discontinued in favor of more modern laser scanners. We sold them up until July of 2015, but the only quality manufacturer of wands is no longer producing them due to much lower demand.

Slot badge scanners require only one hand

for operation; the user simply slides

his badge with a bar code on the bottom

edge through the scanner. These are typically

used in unattended entry/exit stations

for payroll, club membership accounting,

school lunch assistance programs, etc...

Slot badge scanners require only one hand

for operation; the user simply slides

his badge with a bar code on the bottom

edge through the scanner. These are typically

used in unattended entry/exit stations

for payroll, club membership accounting,

school lunch assistance programs, etc...

Slot badge scanners are similar to wand

scanners, but usually refined so that

one resolution can read most types of

bar codes with no difficulty; utilizing

the additional space for larger optics,

a slot badge scanner usually has a vertical

aperture to look at the elements, thus

allowing a high resolution slot badge

scanner to read almost all types of printed

bar codes, from dot matrix to high density.

Slot badge scanners also come with visible

or infrared light sources. Visible can

read any bar code which can be seen with

the eye including bar codes printed on

thermal printers, (infrared cannot read

thermal printed bar codes); infrared

slot badge scanners would be used for

security "black on black" bar codes,

(the black bar code is covered by a black

window on the badge, but the black window

looks clear under infrared light).

There are only a few RF Scanners currently available on the

market. These units have decoder, battery,

and transmitter built into the scanner

-- allowing cordless scanning back to

a base station. Most have a short range varies

from 20-30 feet from the base station.

Shown here is the Worth Data LZ360-RF Cordless Laser Scanner. It has a range of up to 300 feet. It reads 0-12" away from a typical bar code - but will transmit the bar code up to the 300 foot range of the radio to a B700 USB Base Station. Competitive RF Laser Scanners with this RF range cost considerably more. The laser has a "good read" indicator as well as a confirmation "base received data" beeper in the laser scanner, so you don't have to be near the base station to hear a "good read" received. The B700 USB Base Station connects to a PC or Mac via USB as a keyboard (it can also enumerate as a serial CDC USB device on a Windows machine. Up to 10 scanners per base station are possible - and multiple pairs of units can operate in the same location with an easy setup change by the user if required.

Worth Data also offers a more powerful LZ404RF Cordless Laser scanner and a 2D Omni-Directional 520-RF Scanner that uses the same B700 USB Base Station.

There are several methods of getting

printed bar codes; these are:

Whatever printing source you decide upon, there are a few common sense tips to pass on:

If

the only bar code application you are doing

is an application such as fixed asset inventory

tracking and employee badges, pre-printed

serialized labels make a lot of sense. Photo composed

labels  are usually very high quality and

you can buy 5000 for around $500. Libraries

typically use pre-printed labels. Why? Because

the labels need to last for 25 years and

the volume is usually 100,000 per library.

High quality, durable, laminated photo composed

labels are usually used. Worth Data supplies custom Pre-printed Polyester Bar Code Labels - We can even ship the same day an order is placed!

are usually very high quality and

you can buy 5000 for around $500. Libraries

typically use pre-printed labels. Why? Because

the labels need to last for 25 years and

the volume is usually 100,000 per library.

High quality, durable, laminated photo composed

labels are usually used. Worth Data supplies custom Pre-printed Polyester Bar Code Labels - We can even ship the same day an order is placed!

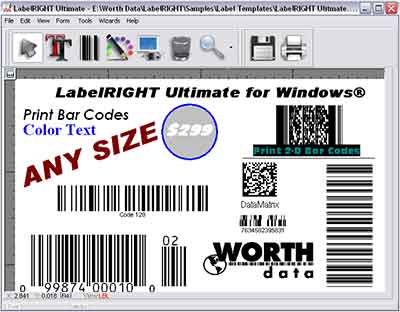

You can also print high quality durable labels on a thermal transfer printer using XT Polyester label stock or on a laser printer with a poly label stock - call Worth Data for our Worth Poly™ Polyester Laser Label stock; such stock is more expensive than paper, but worth it is you need more durability. We also offer our popular LabelRIGHT Ultimate for Windows bar code labeling software so that you can make your own labels on your computer with your printer.

Printing on PC Printers

With the proper PC software, today’s printers are capable of printing excellent quality bar codes. Ink Jet and Dot Matrix printers cannot print high- density bar codes, but laser printers can. Laser printers actually print the best quality bar codes of any commonly available printing technology.

Laser Printing

Laser printers can produce outstanding quality bar codes. The quality is consistent even whentoner gets low; it is obvious and is not subject to interpretation. (When the toner cartridge is changed, it is important to follow the replacement cleaning instructions, including cleaning the corona wire, especially for high density bar code printing.)

Labels are sectionalized on a 8 1/2" x 11" page in multiple columns and/or rows. For example, mailing labels (1" by 2.8") appear in 3 columns and 11 rows, 33 labels per page. Since laser printers feed one sheet at a time, it is impractical to print one label at a time.

There is an unprintable area 1/4" inch to the left, right, top, and bottom of any form; this makes full labels impossible unless you sacrifice the top row and maybe the bottom row of labels. One trick in laser printing is to use label stock with the laser's unprintable areas cut as a border picture frame around the printable label's area.For example, the previous example of 33 mailing labels per page would be 30 labels per page with the unprintable area isolated as a picture frame border. The top and left margin settings in the program would adjust the labeling program to the picture frame label stock's unprintable borders.

Laser printers are great for producing batches of labels, but if you need only one label (where there are multiple labels per page) at a time, dot matrix or thermal transfer printers are required. Laser printing is the best quality of all types. There are several types of label stock available for laser printers. If you need to print durable labels, Worth Data offers a polyester label stock designed especially for laser printers. Worth Poly is made from a special white, matte finish, heat stabilized polyester film designed for laser printers. When printed on a laser printer, the resulting label is heat resistant, water-resistant, light resistant, scuff resistant, smudge resistant, and stain resistant. These labels are ideal for any labels that you want to last through rough handling or harsh environments. The permanent adhesive is designed to keep your label adhered to wood, metal, plastic, or glass for years. You pay a little more, but you get a lot more label for the money.

Windows programs usually give you rich text fonts, more rotations, and excellent image graphics printing. The labeling programs for Windows often support Postscript printers.Ink Jet Printers

These printers are getting better and better. They print pages of labels, so refer to the page label stock discussion below regarding page laser label stock. Also, use label stock specifically meant for inkjet printers – the stock is usually coated to minimize ink bleed. Always test your bar code labels for readability before printing in bulk.

Inkjet printers are almost exclusively supported by Windows programs. If you have problems, check to make sure you are using the latest driver version from the printer manufacturer. Also, be sure to select a printer that has a separate black cartridge in addition to the color cartridge.If labels you are printing are going to be exposed to water, don't use the inkjet printers – most inkjet ink is water-soluble. Inkjet printers are NOT the best printer to use to print labels that need to withstand the weather or are subjected to constant scanning.

Beware; the inkjet cost per page in color is twice the cost of a black and white print.

Thermal Transfer Printing

Thermal transfer printers are required when you need either to print one label at a time or when you need to print a roll of labels so that labels can be applied by applicators directly to boxes.Volume industrial printing is done mostly by thermal transfer printers. They are fast and produce excellent quality bar codes.

Thermal transfer refers to the printhead heating up and melting a ribbon onto the label surface. Most thermal transfer printers can also produce "direct thermal" labels, but paper instead of a soft ribbon wears out the printhead 10 times faster; another disadvantage of thermal printing is that most thermal labels cannot be read with IR light and deteriorate in sunlight to non-readability over time. The media cost is about the same as laser and direct thermal. Therefore thermal transfer printing is far more popular than thermal printing for serious label production.

Beware of the CoStar, Brother and Seiko thermal printers for producing serious bar codes. They have two problems:

- The bar codes are just a little off. (The naked eye can often see three sizes of bars when only two are supposed to be possible).

- They are thermal printers producing bar code labels that will deteriorate to un-readability in sunlight.

- They are inexpensive, so they are very attractive, but beware.

Most popular thermal transfer printers can produce labels up to about 4" wide (more expensive models can print at 6" or even 8") and lengths up to 8 inches plus. Smaller widths can of course be accommodated. Popular thermal transfer printers are manufactured by Citizen, Sato, Zebra, and Datamax; these are the major brands.

You can get almost any type of label stock imaginable for thermal transfer printers; high temperature, weather proof, surface laminated, jewelry ring stock, card stock, tag stock, etc.

The basic paper labels with inexpensive ribbons produce bar codes that can be smeared or smudged with hard rubbing by the fingers. Smudge proof labels can be produced with more expensive synthetic label stock and a ribbon with less wax and more resin (hybrid or P2 Ribbon). Scratch- proof laminated labels can be produced with XT Polyester and a high resin ribbon; when heated, the resin and polyester coating fuse to make a very durable label.

These printers generally print from 2" to 12" per second; at any width up to the maximum, the printers print 2" to 12" lengths per second. Find out if the rated speed quoted for the printer you are considering is to be expected when printing bar codes or graphics - for this, many printers slow down to less than 1/2 their quoted speed.

The print heads wear out on thermal or thermal transfer printers. To maximize the print head life, clean it between every ribbon change with a cleaning card or with a lint-free q-tip soaked in alcohol - a MUST to avoid continually replacing print heads. Unlike most dot matrix and laser printers, the thermal transfer printers discussed have scalable text fonts and bar code fonts resident in the printers firmware. The software necessary to print the bar codes is a series of special command sequences. So you can add printing on a thermal transfer printer to one of your existing programs, providing there is someone semi-skilled at programming.

However, most users want a general purpose design labeling program which requires no programming. Our LabelRIGHT™ Ultimate for Windows label printing software supports many Thermal Transfer Printers that have a Windows print driver. LabelRIGHT Ultimate is very powerful and easy to use.

Dot

Matrix Printing

Dot matrix printers can

produce good quality low volume bar

code labels. When printing low-medium (3.7cpi

or lower for Code 39), the labels can

be excellent quality. The Epson®, IBM,

and Okidata® printers have adequate

graphics capability to yield good quality bar

codes. You will need a dot matrix printer

with a pin feed platen to successfully

print the variety of label sizes.

There's one catch though - you must not wait too long to change the ribbon. The printer operator must make a judgment call on when to change the ribbon. It's best to tape a bar code of minimum acceptable darkness on the printer, so the operator can't make a judgment error. Programs that can strike the bar codes multiple times can keep the ribbon expense down.

Both 24-pin and 9-pin printers can produce good quality bar codes. The 24- pin printers produce better bar codes than 9-pin printers, especially as the ribbon is getting low on ink. The 24-pins simply put more ink on the paper.

Because

dot matrix, Inkjet and Laser printers are in such widespread

use, labeling software to make these printers capable of printing

bar codes has become readily available. There are two general

types of bar code printing programs available:

Stand-Alone Menu-Driven Programs

These programs allow the

user to design different label formats

and save them to disk for label runs.

Usually there is a WYSIWYG design interface

to view the label on screen as it is

bein g designed, especially Windows programs.

These programs usually have most of the

following features: scalable fonts, graphic

image import, all popular bar codes,

data file import, easy custom operator

interface, popular data base access,

and/or built-in label data base. Look

for a program that combines support

for laser/dot matrix with thermal transfer printers like our powerful LabelRIGHT Ultimate for Windows software.

g designed, especially Windows programs.

These programs usually have most of the

following features: scalable fonts, graphic

image import, all popular bar codes,

data file import, easy custom operator

interface, popular data base access,

and/or built-in label data base. Look

for a program that combines support

for laser/dot matrix with thermal transfer printers like our powerful LabelRIGHT Ultimate for Windows software.

Besides the ability to design and print labels, you should look for a program with a simple operator interface. The label designer creates custom prompts for a label format; then the operator answers simple questions that lead him to enter the variable data for the labels to be printed. With a label database, you can select which labels to print. You don't want the operator to have to deal with the more complicated label design screens.

In Windows and Macintosh environments, any font based program can select fonts for printing. This makes it possible to use bar code fonts from such programs (i.e. Word®, Excel®, PageMaker®, Quark®, etc.). Problems which must be overcome are:

Using fonts, labels can be printed from your favorite word processing program, or you can add bar codes to a form from almost any font-based Windows program, (provided your program can call our DLL). Our LabelRIGHT Ultimate for Windows software package has a powerful font package called BarFont™ that simplifies using fonts in other Windows software.

Bar Codes on Packaging or Film Masters

How to Get a UPC Number

If you haven't already been assigned your manufacturer's

number by the GS1-US (formerly the Uniform Code Council) or appropriate GS1 authority for your country. Call the GS1-US at 937-435-3870 to get a registered UPC number. You will pay a charge

to get a manufacturer's number assigned, (digits 2-6 in the UPC

code), plus you will get an information packet. You will be assigned unique UPC numbers for all your products.

For users who wish to have the bar codes printing as an integral part of their packaging (such as sugar bag) there are three ways:

After printing, the ink

in bars tends to bleed slightly into

the spaces. Therefore, bars on film should

be slightly narrower, (probably 1/1000

inch narrower), to allow for the spreading

of the ink in printing. (Turn down the

darkness on the laser printer if printing

bar codes on paper to be photographed.)

Whatever method you use, you should have your printer make test

print runs. If you don't use a verifier to test the accuracy of

the bar codes, at least:

Don't forget to leave a 1/4" white space to the left of the leftmost bar and a 1/4" white space to the right of the rightmost bar, (no text or other graphics in these areas).

Bar Code applications are growing by the day as creative people

find ways to enjoy data entry efficiency possible with bar

codes. The following is a brief discussion of some major

applications: (the key to all of these applications is the

software; the software is the steak, the bar code is the

sizzle).

Data Capture Applications

Assembly Checking

usually done with custom assemblies, a terminal leads the operator in what to assemble; as the operator scans each part or subassembly added, the computer can monitor for correct specifications.

Fixed Asset Inventory Control

Large organizations have multitudes of furniture, PC's, fixtures, etc. The exact location for each item determines cost allocations. Bar codes are placed on all items and bar codes are placed on walls of each location. With a portable bar code reader, the location is wanded and then all items in that location are wanded; the data is then uploaded to the computer for accurate depreciation cost allocation.

Job Costing and Tracking

As item(s) are completed, scanning results into a terminal. (Multiple operators use a single terminal).

Labor Distribution

Again using employee badges, as employees move from department to another, the employee scans in his badge at the new department's terminal. This allows payroll cost allocation to departments.Library Automation

Bar codes on ID cards of patrons and bar codes on books. Automatic check out.

Meter Reading

Similar to a pick list, but downloading to portable terminal the list of addresses to be read, along with the bar code ID of the meter, so that the terminal checks that the operator is indeed reading the right meter.

Order Books

Catalogs of items with associated bar codes. Used for order taking, estimating car repair costs, route accounting, etc.

Point of Sale

At the cash register (or equivalent), scanning the bar code into a computer which looks up the item scanned and displays the description and price plus decreasing the on-hand inventory by the quantity purchased.

Records Management

For patient records, case records, loan records, etc., a bar code is placed on the folder. Then as the units are checked out, the folder is scanned and the borrower's ID card is scanned. As the unit is passed from one station to another, the item is scanned so that it can be tracked through the organization.

Remittance Processing

Printing a bar code on the remittance stub or the invoice stub so that when the customer returns the stub with his payment, it can be wanded to bring up the data or to complete full payments.

Stock Taking

The classic portable bar code reader application. The operator scans the codes of the items (perhaps scanning only one of multiple items and then entering the quantity for that item) and then uploading the stored scanned data to the computer later, thereby correcting the computer's files for what is actually on the floor.

Time and Attendance

Employee badges with bar codes are read at clock-in and clock-out into a computer or terminal to provide attendance data to the computerized payroll program.

Warehouse Picking

The computer downloads a table to a portable terminal and the operator is prompted to pick a list of items associated with a specific order. After picking the order, the operator goes back to the terminal to upload the data and receive his next order to pick. As locations are reached or items are picked, the bar codes are scanned and the terminal compares what was scanned to be sure the right location or item is being picked.

Warehouse Put-Aways

As the operator stores items in a warehouse, the operator scans the items and the location. This data is then uploaded to the computer so it can keep track of the inventory quantity on hand and locations.

Warranty and Service Tracking

As units are received, the bar code on the case of the unit is scanned, bringing up the computer history for that unit. As the unit is repaired, scanning what failures and what new parts are required to repair for costing and failure analysis.

Work-In-Process Inventory Tracking

With on-line readers or portable readers, scanning the routing sheets with bar codes on them as parts or subassemblies are completed, often including yield data, so the work-in-process costs and progress can be tracked. (Usually one terminal per operator).

Event

Time Applications

There is now a variety

of hand held bar code terminals which

are linked by Radio Frequency (RF) back

to a host computer. This makes possible

portable interactive applications in

the stock room, the warehouse, shipping,

receiving, etc.

Whatever the cost of the hardware, the application software investment

is intense for most companies. It is really an extension of MRP

II software into the portable hand held terminals.

Applications include:

Rental Car Check in and Billing

Anyone who has rented a car lately has experienced the convenience and speed of RF Terminal check-in at the curb.

Massive Table Lookup

The simplest application is the computer performing validity checks on data entered from its large up-to-date computer files and notifying the operator of any invalid data.

A classic example of this would be grocery price validation. Instead of downloading a 10 MB file into a hand held, the computer does the table lookup and lets the operator know what prices need to be changed on the floor. Any store without prices on the items must have price validation by RF Terminal to be sure the prices on the floor are the same as the price in the computer. Direct Store Delivery by vendors is also a must for RF Terminals, allowing the store to monitor the price being charged by the delivery personnel to the store.

The best example is stock taking. Based on the outage or overage, the computer would instruct the operator in different things to do: count again, see supervisor, etc. The counts could be double checked on the spot, yielding a faster more accurate inventory count.

Receiving

As a purchase order is received, the operator scans and keys what has been received, with the computer pointing out shortages that are double checked on the spot rather than after the items have been moved or partially used.

Shipping

As items are loaded, they are scanned. Shortages or miss-loads can be detected immediately.

Put-Aways

As items are put away, the computer has them immediately available for picking to satisfy the next order.

Warehouse Picking

The computer instructs each picker what to do with up to the second stock status from Put Aways. This would be especially valuable with items in multiple locations and where substitutions are possible.

To

get a manufacturer's number assigned for UPC

bar codes, call

GS1US: 937-435-3870

For industrial laser scanners,

call

Microscan:

800-251-7711, or in WA 425- 226-5700

Durable Polyester

Laser Labels, call

Worth Data: 800-345-4220, 831-458-9938

For dot matrix, Thermal Transfer,

and paper laser labels, call

Ardon Business Forms: 800-853-1223 Or 248-377-6160

For metal

tags or labels,

call

Metalcraft

Inc.: 800-437-5283,

or 515-423-9460

Express

Inc.: 800-382-2323 or in CA,

858-.549-9828

For

thermal transfer labels and thermal transfer

ribbons, call

Worth

Data: 800-345-4220, 831-458-9938

- Very Few Sizes and Types in stock

DataMax:

800-816-9649 - Many Sizes & Styles In Stock

Mabi

Label: 800-969-8989 or 408-283-1600 - Custom Sizes

For bar code verifiers, call

Accugraphix:

800-654-0479, in CA 714-847-6674

For badges and badge supplies,

call

Caulistics: 415-585-9600

For Code 39, I 2of5, and Codabar Specifications,

write

ANSI Sales Dept.: 1430 Broadway,

NY, NY 10018. Enclose $9

212-642-4900

For most other bar code specifications (fee),

call

AIM USA: 412-963-8588

For AIAG information

(Automotive Industry Action Group), call

AIAG:

248- 358-3570

For Film Masters, call

Symbology Inc: 800-328-2612

PrePrinted Bar Code Labels, call

Worth Data: 800-345-4220, 831-458-9938 or Order Custom Labels Here

Data2: 800-227-2121

Bar Code Readers, call

Worth Data: 1-800-345-4220, 831-458-9938

Laser Scanners, call

Worth Data: 1-800-345-4220, 831-458-9938

Radio Frequency,

call

Worth Data: 1-800-345-4220, 831-458-9938

Portable Bar Code Readers,

call

Worth Data: 1-800-345-4220, 831-458-9938

Labeling Software & Fonts for

Windows, call

Worth Data: 1-800-345-4220 , 831-458-9938